Its amazing how fast time flies. I can hardly believe its been a year since I started this project. Before I provide my update, I want to do a 'Then and Now' reflection. I'm amazed at the progress I've made and I can actually see light at the end of the tunnel. The only part on the car I haven't touched is the bonnet and that is because it doesn't need much work. If life would stop interrupting my fun, I could finish this project.

My original goal was to complete it in a year but now with that date past, I will try to complete it before the Oil Leak tour in October. Oil Leak, you question? It is an annual event where a group of fellow British car lovers get together for a week and see some of the sights our great country has to offer. Its a really low key trip with people who not only like to restore their cars but drive them too.

Anyway, here are some Then and Now Pictures:

I brought home a rust ridden, multi-piece ready for the scrap yard car

Now, its rust free and one piece. It is beginning to resemble its original design. No longer is it destined for the scrap heap. It has a bright future ahead of it

Before putting these pictures together, I've not really reflected on just how much work I've done over the past year. When I started this project, I estimated about 1000 manhours to complete it and I think I'm still on target for that or maybe just under. I've probably spent 600 hours on it so far and have done most of the hard work. I still have to spend some quality time with the doors but can't do that until I get all the chrome back.

Now, for some more progress pictures:

I just mentioned getting the chrome back. It took awhile but it is starting to get done. There were a few pieces I sent off, they declined to chrome or gave me the option to just replace instead. So far, the pieces they didn't want to do are readily available and probably cheaper than I could repair/ rechrome. Of the remaining pieces, the one I am most concerned with looking good, is the grill. From the very beginning, I was concerned about a missing fin. I found a very nice thread on jaglovers xk120 Grill Project where a guy made brand new ones and I was prepared to do the same. Miraculously, the missing fin was among the parts I sent to be chromed so I don't have to make it now.

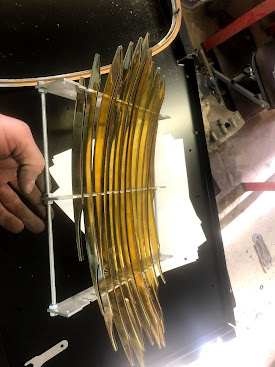

As others had mentioned, the chrome shop recommended disassembling the grill for stripping and polishing. They said I could do it as one piece but the sides of the fins would not get polished and therefore would not look like new. Taking their advice, they gave me back the grill and I unsoldered all the fins. This was not very difficult as they are not brazed in and a propane torch worked quite well. Propane isn't hot enough to effect the brass plating. By removing the fins, I could also replace 2 of the studs that broke when I pulled the grill from the bonnet. Those I brazed back in so they would be stronger than just solder.

| ||

A quick check to ensure the fins fit properly

|

|

| To make sure I wasn't going to have an issue when I went to mount a newly chromed grill, I did a test fit. Fit right into place, I'm very excited about it. |

After a long hiatus, I decided to get back to some of the remaining body work. My initial focus was on the boot section, posts and sills. Once those were complete and the car back together, I turned my focus to the frame and mechanicals. Now that I'm continually in holding patterns, waiting for parts, I've filled my time with the bonnet section.

|

| The passenger side wasn't as bad but still bad |

|

| This was a test fit before grinding down all the welds underneath |

|

| Same for the other side. You can see my alignment marks to ensure I put the new one back in the same location |

|

| Not the final picture but close. Now, the only spot left to replace is the lower edge of the bonnet nose on the driver's side. |

|

| And here is the final picture with all the welding and grinding done. Just a little feathering with some body filler required. |

Another project I tackled was the bonnet hinges. At first glance, I thought these hinges had already been restored. They looked fairly clean but did seem a little stiff. I thought maybe they were just stiff by design so I installed them. I discovered they are NOT stiff by design. Even after risking damaging the bonnet by open and closing the hood a few times did not help loosed them up. Thanks to Bob, Bob's Hinge, I decided to do the same.